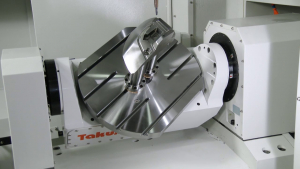

Takumi’s U series of 5-axis machining centers are consistently designed to meet mold and die requirements as well as enable fast and precise machining of workpieces with high surface quality.

Takumi’s U series of 5-axis machining centers are consistently designed to meet mold and die requirements as well as enable fast and precise machining of workpieces with high surface quality.

One of the outstanding features of Takumi’s compact U series is its pronounced mechanical and thermal stability. The U 400 and U 600 models have a portal design, whereas the U 800 features gantry construction. As a result, the machining centers are extremely robust and have a high level of structural rigidity, which in turn allows for highly precise and dynamic production.

The primary differences between the versions ─ in addition to their design ─ have to do with the sizes of their rotary tables as well as the maximum table loads. Moreover, the U 800 is driven on the A and C-axes by means of torque motors. What do all the designs have in common? The direct drive units feature high drive torque and powerful clamping torque. They are also virtually wear-free and therefore require very little maintenance. Included in the standard equipment of the U series are glass scales, an oil cooler for the spindle, and the internal coolant supply through the spindle assembly. This makes the spindle resistant to high temperatures during prolonged program operating times in addition to its already smooth running characteristics.

As is the case with all Takumi machines, the U series also features a Heidenhain control system that allows for programming in dialog and in parallel mode and also includes functions for free contour programming and ISO-NC programming.

Zdroj/ Foto: Takumi