This contribution presents the design of a new technical solution of the truck superstructures, trailers or semi-trailers, the so-called basic frame or removable transport frame resp. „Abroll“ [5], with function for additional installation of the containers, living containers, cisterns, platforms and so on by simple sliding to these superstructures. The removable transport frame is slide to components applied to bottom part of other superstructures.

This contribution presents the design of a new technical solution of the truck superstructures, trailers or semi-trailers, the so-called basic frame or removable transport frame resp. „Abroll“ [5], with function for additional installation of the containers, living containers, cisterns, platforms and so on by simple sliding to these superstructures. The removable transport frame is slide to components applied to bottom part of other superstructures.

Using this sliding transport frame it is possible to slide up truck, trailers or semi-trailers, slide down and in combination with carrier of removable superstructures NVN – S3 [8] also dumping the other superstructures to the three sides. This solution increases utilization efficiency of one type of transport frame and truck for many functions and so allow save total costs and time.

Introduction

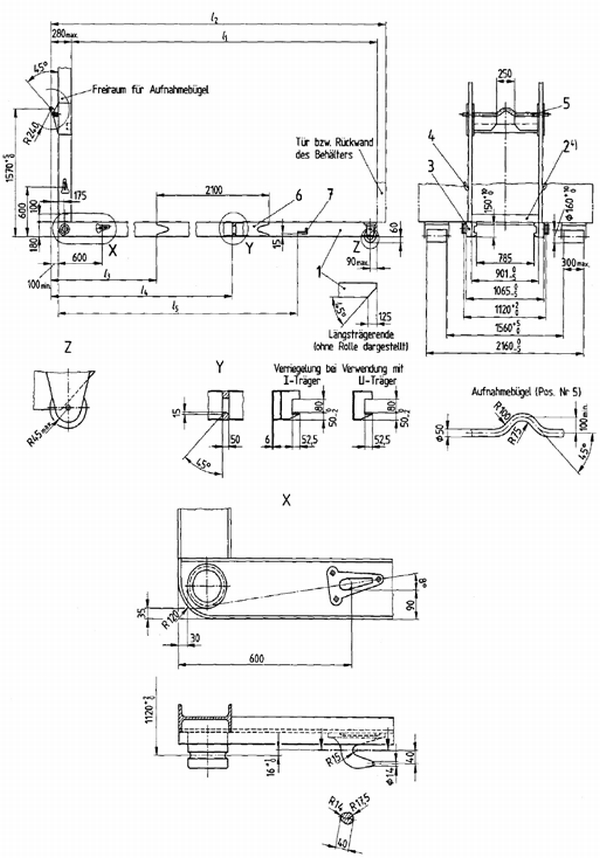

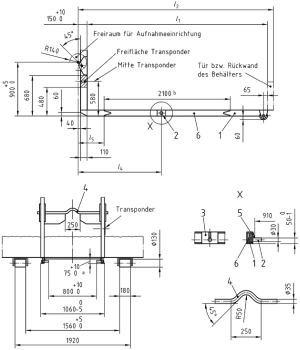

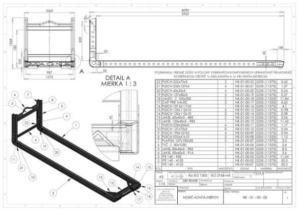

In the present are designed basic frames, from structural view, as elements of other superstructures or as individual basic frames. In the case, that basic frame is designed as a sub-frame of superstructures, application of other superstructures to basic frame is realized by their welding to frame and than is frame sub-frame of relevant superstructure. If the basic frame is designed as individual frame, application of other superstructures to this frame is usually realized by bolted joints (Fig.1).

One from standard systems combined transport in the part of railway – way, using basic frame as a part of superstructures, is Abroll-Container-Transport-System.

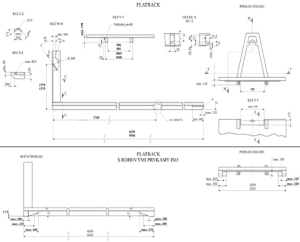

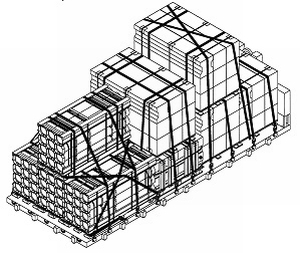

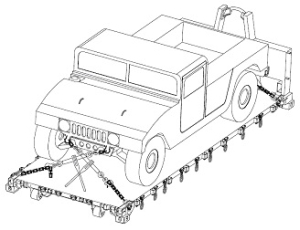

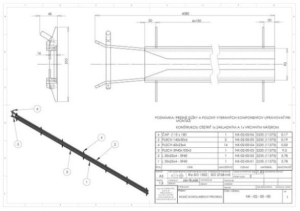

To the group of individual frames, with characteristic type of attachment of transported elements, also belong demountable load carrying platform, called Flatrack [6]. The system of carrying platforms – Flatrack arises from conception of the DIN 30 722 [5] and STANAG 2413 [6]. These carrying platforms are usually used in the frame „Palletized Load System“ in the army. These frames have simple structure and simple type of attachment of transported elements (fig.5, 6).

|

|

The superstructures, usually in the form of containers, are standardly using these basic frames and using hook loaders to the truck, trailer or semi-trailer slide up, slide down or can be tilted by types of superstructure attachment to the basic frame to the back side.

|

|

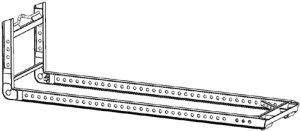

In this context was designed individual removable transport frame, which is possible to slide up under the other superstructures and to combine apart from transport the other types of superstructures also their slide up to the truck, slide down from truck and in combination with system of NVN – S3 [8], by demand also their dumping to the three sides.

The Present State of Basic Frame Solutions

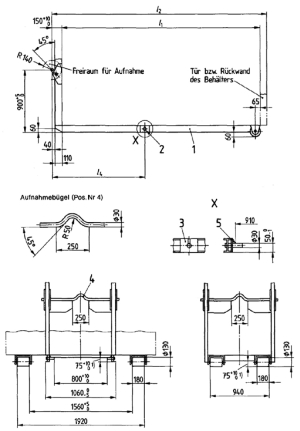

After study of the accessible documents are on presented figures bellow shows present structural solutions of basic frames „Abroll“ and „Flatrack“ by relevant codes [5, 6].

Design of New Solution of the Removable Transport Frame

The removable transport frame is from structural view projected in the form of individual frame with components for attachment of superstructures applied to the bottom side of other superstructures. To the basic frame it is possible additionally to apply components for attachment of transported elements, similarly as about frames “Flatracks” (Fig.6).

|

|

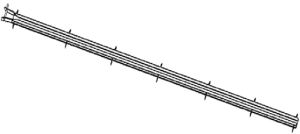

The structure of basic frame is solved as system assembled from longitudinal supported parts connected by traverses to the curved-closed frame. The elements of frame are combined from opened and closed cross-sections. Opened cross-sections are reinforced by demand. In accordance with weight and type of loadings of frame structural components it is possible to reduce mass of some components by means of routing (Fig.7, 8).

|

|

|

|

The removable transport frame is connected to hook loaders or NVN – S3 system [8] mechanically, hydraulically or other way, as well as combined. To the other superstructures are attached frame components (Fig.8, 9) as opposite parts of along supported elements. For simplicity of sliding up and down of frame from components are ending parts of components, as also ending parts of basic frame properly structurally adapted and is suitable used lubricating substance. Locations and dimensions of some parts of removable transport frame are designed in accordance with conformity the other structure of hook loaders, or NVN – S3 and relevant superstructures. The structural solution and function removable transport frame are evident also from attached figures.

Strength Analysis of the Removable Transport Frame

By requirements of solution, in terms of design, was in structure of the removable transport frame realized a static linear stress and strain analysis by finite element method (FEM). It was simulated some load cases of frame structure and components arising from function of removable transport frame for example sliding up, sliding down, lifting, sided dumping, back dumping and so on.

According to the loading type and structural parts composition of removable basic frame are, from strength view, critical places in areas of structural elements which create internal corners, i.e. stress concentrators. Therefore it is preferred analysis of stress, strain and displacement distribution in internal areas of connections of frame support structural elements and in the area of hook action of hook loader.

From function view is important analyze deflections of horizontal I sections, during sliding load case of frame under container, which must correspond with dimensions of component structures for reliable function of sliding.

From structural view is removable transport frame in accordance with criterions and recommendations defined in the STN EN 1990 (EC0) [4], STN EN 1991 (EC1) [3], STN EN 1993 (EC3) [2] and DIN 30 722 [5]. Technical solution of removable transport frame and relevant components is supported with complete drawing documentation for manufacture and development.

For protection of this technical solution was elaborated application form for registration utility models in order to be registered into the Industrial Property Office of the Slovak Republic.

One truck, trailer or semi-trailer with carrier of removable superstructures NVN – S3 [8] and removable transport frame is possible to use also for three sided dumping. In this conception is removable transport frame more universal, with wider range of his utilization. Using this structural solution of basic frame is possible decrease global costs and time.

The removable transport frame can be utilized in various industrial sections, for example civil engineering, mechanical engineering, in army, for transport living containers, cisterns, three sided containers, platforms, over size and special loads and so on.

|

|

|

Conclusion

The new structural solution of removable transport frame „Abroll“ with components for flexible attachment of superstructures is distinguished with a simple structure, which allows transport, lifting, sliding up and in combination with NVN – S3 [8], as well as three sided dumping other superstructures to trucks, trailers or semi-trailers.

Components of removable transport frame can be applied to other exist structural solution of superstructures with only small structural adjustments.

During design of removable transport frame for a certain type of truck and the hook loader it is possible to use either drawing documentations these devices or models created by means of digitalization tools and software in “reverse engineering”.

Device of removable transport frame „Abroll“, with components is distinguished with low production costs, low weight, saving of materials and costs for manufacture and procurement of other types of superstructures.

Acknowledgements

This article was prepared on basis of cooperation with the firm MAGNA – VTZ Ltd. and during solution of the project VEGA 1/0356/11 Innovation processes in structure of driving elements of transport devices, machines and optimization of material flows and logistics for purpose saving energy and increasing responsibility for applications in practice.

References

[1] Renault Trucks – Guides and manuals for the fitting of bodywork for the Renault Midlum,

[2] eurokód 3 (EC3) – Design of steel structures, CEN,

[3] eurokód 1 (EC1) – Actions on structures, CEN,

[4] eurokód 0 (EC0) – Basis of structural design, CEN,

[5] DIN 30 722 – Abrollkipperfahrzeuge, Wechsellader-Einrichtung Abrollbehälter,

[6] STANAG 2413 – Demountable load carrying platforms (DLCP/FLATRACKS),

[7] Jenkins, T.: Tie-down handbook for truck movements, Military Surface Deployment and Distribution Command, Transportation Engineering Agency, 2008,

[8] Burák, J., Schneider, M.: Nosič vymeniteľných nadstavieb NVN – S3, Magazín stavebné stroje a mechanizácia, 05 – 06/2011.

Reviewers: Dušan Oravec – MAGNA – VTZ s.r.o., Košice, Slovak Republic, Doc. Ing. Oskar Ostertag, PhD. – Technical University of Košice, Fakulty of Mechanical Engineering, Department of Applied Mechanics and Mechatronics, Košice, Slovak Republic

Authors: Ing. Ján Burák, PhD., Ing. Marek Schneider, Technical University of Košice, Faculty of Mechanical Engineering, Department of Machine Design, Transport and Logistic.